CIRIMAT-Toulouse - Isabelle PASQUET

Direct shaping of oxides by laser insolation of transition metal oxalates

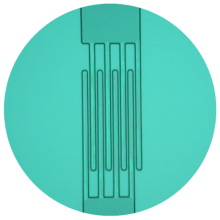

Films of copper and cobalt-iron oxalates were prepared from suspensions of powders in ethane-1,2-diol deposited on glass or polycarbonate substrates. Two-dimensional structures of oxides, resolved on the scale of less than ten micrometers, were formed by laser insolation of these films, using a photolithog-raphy machine. The nature of the constitutive phases of the oxides formed tends to show that the laser heating makes it possible to reach locally, temperatures higher than 1000 ◦C. The oxides formed are thus sintered. The residual oxalate can be removed by washing or dissolving, leaving the oxide structure on its substrate. In spite of a perfectible sintering, the formed structures could interest different technological applications (electronic or magnetic devices, gas sensors, photovoltaic systems. . .) requiring the shaping of simple or mixed oxides on a scale close to the micrometer. The process of selective laser decomposition of oxalates, could subsequently be suitable for additive manufacturing of 3D parts.