What should be the criteria for choosing a direct laser writer?

The quality/rendering of the imprinted patterns:

-

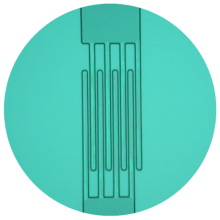

Quality = Minimum roughness

Vector mode highly recommended to benefit from the smoothest contours definition.

Good news! Kloe systems offer Real Vector Write Mode, and hence this level of minimum roughness :)

-

Quality = Very large Depth of Focus

It enables to ensure the same resolution to be kept on the whole surface, without having to resort to an autofocus system to compensate lack of depth of focus, and to reduce the risk of unexpected defocusing.

Good news! One of the key point with Dilase technology by Kloe is to provide a unique optical treatment point with an unequalled depth of focus.

No efforts are demanded to an autofocus system (that’s why our equipment don’t need autofocus system, which choose by itself the focusing point ;) ) or to the user to ensure resolution to be kept over the whole surface, whatever the substrate type of thickness, the substrate or photoresist reflectivity…

-

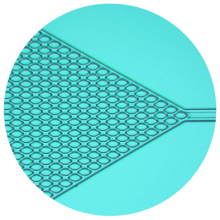

Quality = capacity to write in thin layers as well as thick layers of resin

In Microfluidics application, it is very common to use large thicknesses of resin, whereas in Microelectronics application, the resin layers used must be as thin as possible.

Good news! The unique optical treatment chain provided by Kloe, and its very large depth of focus, enables the writing into thick photoresists with the same rendering than into thin films, with an aspect ratio warranty at minimum 1x20 :)

The writing speed for the imprinted patterns:

-

Best writing speed = Best productivity

Yes and No ;) : fast scan only makes sense when quality scan can first be obtained and with comparable quality.

Good news! At Kloe, our main concern is first that our customers are fully satisfied by the rendering quality of their process, before optimizing writing times :)

-

Balance between writing quality and writing time

After favoring the achievement of High Quality patterning and fidelity to the design, it is important to optimize writing strategies to meet the objectives in terms of productivity.

Good news! Kloe Technology can obviously be very competitive in terms of writing speed, since our stages velocities can be also very fast :)

In summary:

At Kloe, we will always focus first on the respect of the resolution, the respect of the trajectories, the accuracy… Once these steps have been validated, we will be more than happy to help you trying to optimize writing time, thanks for our 21 years of experience of Microfabrication techniques and advices. Don’t hesitate to contact us!