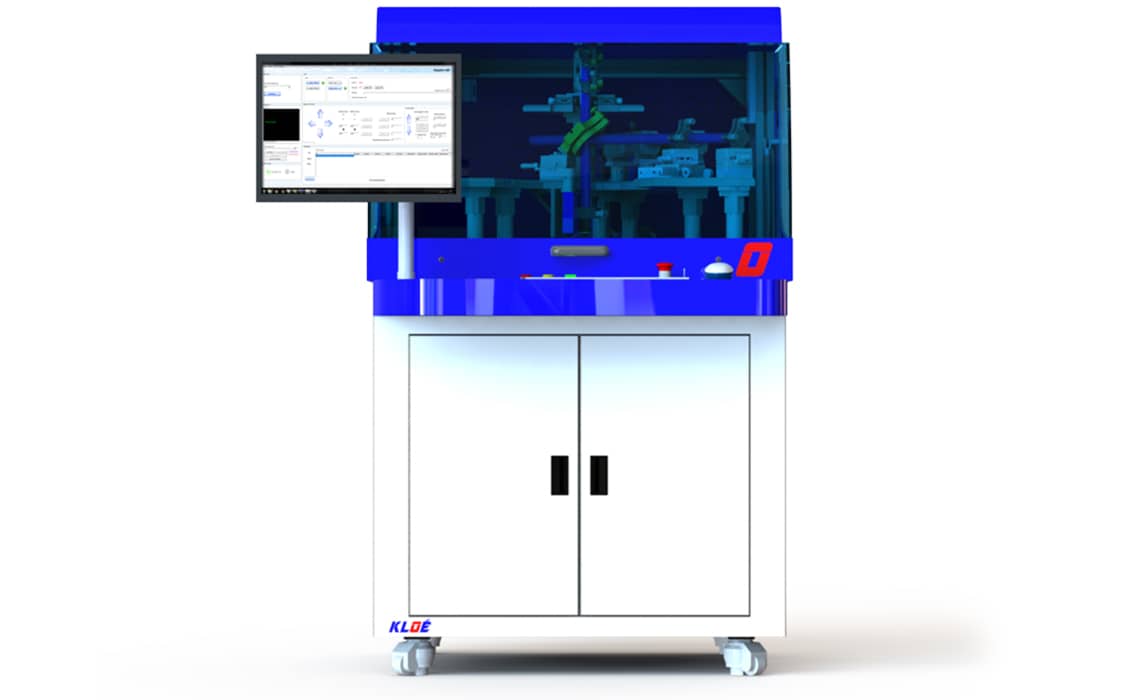

Dilase 650 - Multifunction maskless lithography equipment

Direct laser writer

The high resolution direct laser lithography system Dilase 650 offers you the possibility to work with one or two writing lasers, to be focused into one or two beam sizes ranging from 1µm to 50µm automatically switchables. It allows the writing on any type of substrate (photolithography masks, semiconductors, glass, polymers, crystals, flexible films...) over a surface area as large as 6 inches.

An innovative technology

Kloe has developed a new approach of laser photolithography that is mainly sustained by two major innovations:

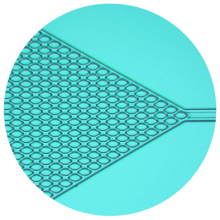

Vector writing mode

Combined with raster scan writing, it ensures a perfect rendering of edges whitout stitching nor roughness, without compromising between rendering quality and achievement time.

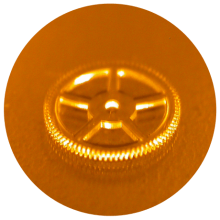

Specific optical treatment line

That induces a large depth of focus and guarantees a perfect performance stability of the equipment. A specific option allows to reach aspect ratios of 1X50 and therefore to write into really thick films on a single pass.

Multifunction laser lithography system

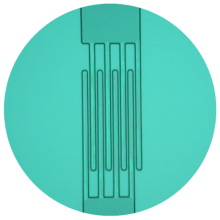

High aspect ratio

The direct laser writer Dilase 650 is equipped with a very specific and unique optical treatment line developed by Kloe that offers you the possibility to achieve microstructures with a high aspect ratio of 1x50 with a single writing pass with the same ease of use as with thin layers.

Specific softwares for multifunction maskless equipment Dilase 650

Dilase 650 is equipped with the software suite DilaseSoft and KloeDesign, perfectly suitable for the manufacturing of prototypes or production devices.

The computer assisted design software KloeDesign

With KloeDesign, you can easily upload the usual standard format DXF and GDSII: this software allows to conceive from simple to more complex designs intuitively. It is provided with a variety of components to be adjusted and assembled graphically.

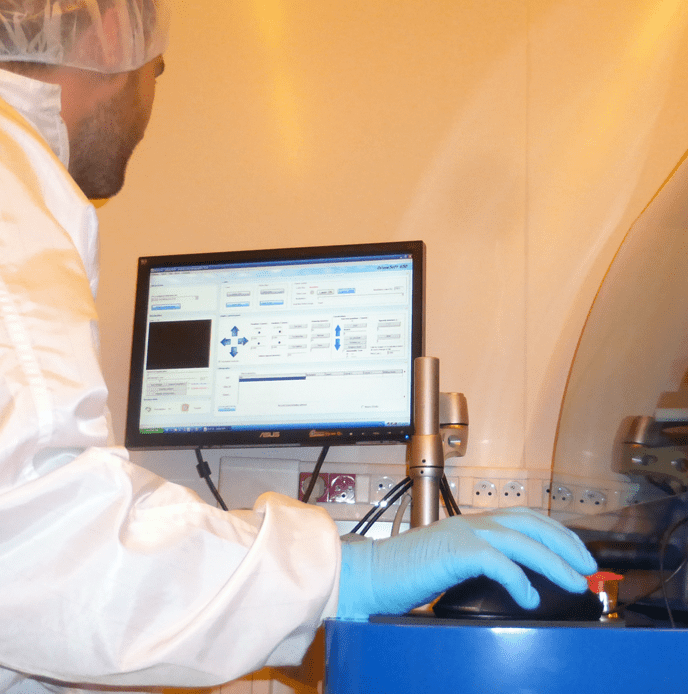

DilaseSoft to drive with intelligence

DilaseSoft, the Dilase systems’ software interface, manages the plateforme that equips our direct laser writer Dilase 650. This software requires the use of a dedicated personal computer to communicate directly with the Dilase system.

- Linear writing speed: up to 500mm/s

- Address grid: 100nm standard, 40nm optional

- Repeatability: 100nm

- Accepted sample size: from 3x3mm² to 4” or 3x3mm² to 6”, 5” or 7” for square substrates

- Accepted substrate thickness: 250µm to 10mm

- Laser beam width (1 or 2): from 1µm to 50µm, 0,5µm optional

- Aspect ratio: 1x20 standard, 1x50 optional

- Multilevel alignment accuracy: down to 250nm

- Dimensions: 935 x 1300 x 1620mm

- Available laser sources: 375nm or 405nm

- 1 or 2 beam sizes

- Video realignment system

- Accepted files format: DXF, GDSII, LWI

- Motorized focal stage

- Integrated design software: KloeDesign, DilaseSoft

- Three writing modes: vectorial, scanning or a combination of both

- Testimonial of Dr Steven Johnson from York University about the direct laser writer Dilase 650

- Other equipment from Dilase range

- Masker and mask aligners from UV-KUB range

- High resolution 3D Printer Dilase 3D