Mask aligners and maskless lithography system: our products

Since 2006, Kloe designs, develops and manufactures a complete range of equipment dedicated to high resolution photolithography with or without photolithography masks

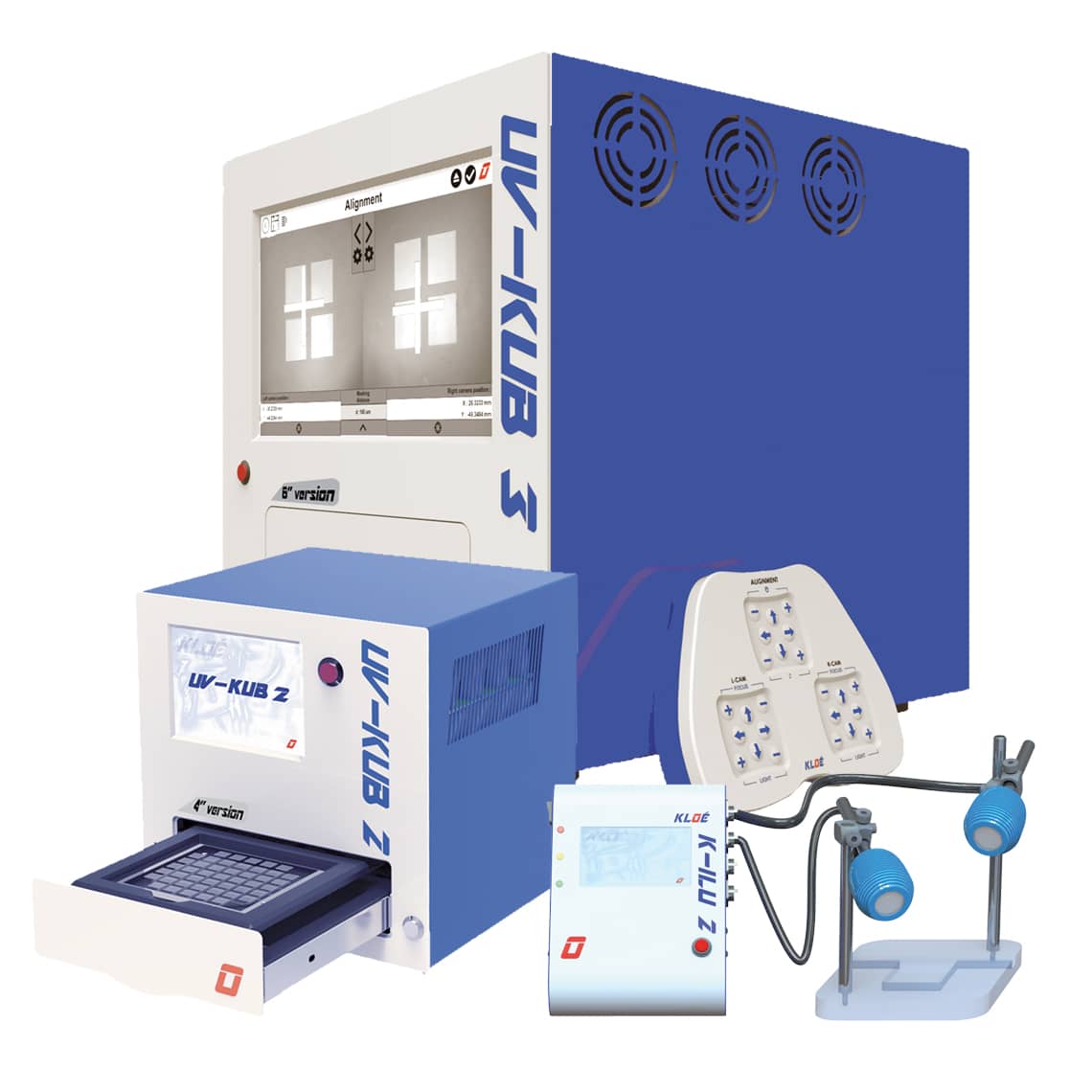

UV-LED maskers and mask aligners: the UV-KUB range

Our UV-LED maskers and mask aligners offers a number of advantages:

- Ease of use, totally controlled by a touch-screen

- Long life-time from the source to the UV LED at 365nm

- The cold monochromatic UV source prevents negative thermal effects

- Can be used outside the cleanroom, thanks to its completely closed and compact configuration

- Adjustable power emission

- Choice of continuous isolation or by a series of pulse where the duration and the power can be adjusted

- No need of maintenance

Furthermore, our new generation of mask aligners, UV-KUB 3, available in 4 or 6 inches version, integrates all innovative technologies from the last few years such as:

- UV-LED light source in place of old Hg lamp

- CCD cameras in place of binocular

- an easy-to-use joypad, user-friendly for the realization of the alignment

- an on-board PC offering the possibility for image capturing, metrology and above all the recording of the alignment masks coordinates to enable automatic pre-alignment of the two visualising cameras.

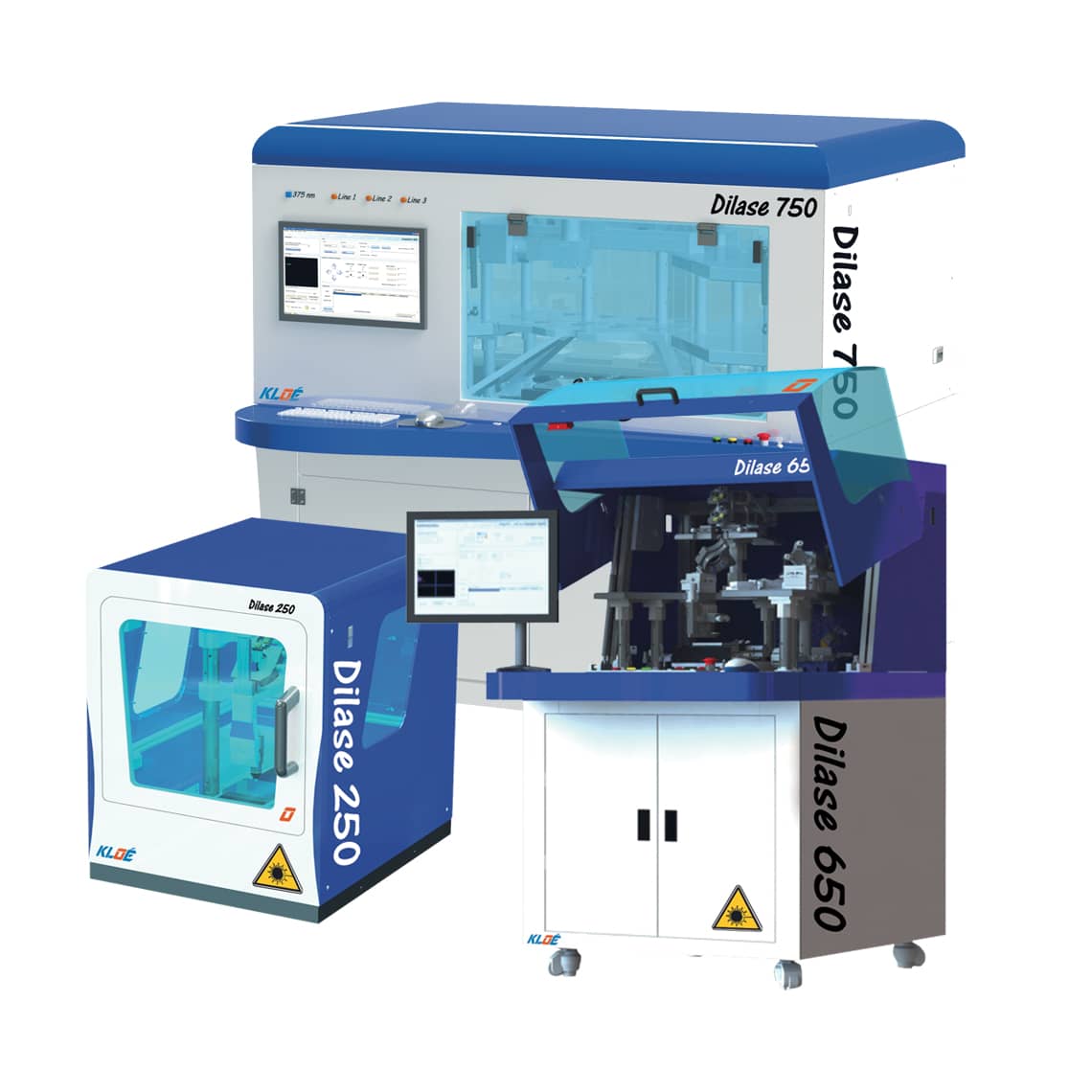

Maskless lithography equipment:

the Dilase range

Very large depth of focus

The Dilase technology delivers numerous innovations and unique specificities on the market of technologies dedicated to direct photolithography by laser. Notably, the capacity to write in thick resist layer until several hundred of microns with a single laser sweep, thanks to specific optical treatments that guarantee a unique very large depth of focus, 1x20 minimum aspect ratio warranty.

This large depth of focus, unique in the market of lithography equipment with or without photolithography masks, opens the door for high-resolution optic photolithography to numerous applications such as microfluidics, guided optics, surface functionalization and micromechanics.

3 writing modes avalaibles: vector mode, scanning mode or a combination of both

The Dilase technology also offers the possibility to write in vector or scanning mode or a combination of both writing modes on one same pattern. It is also possible to modulate the write velocity at will in vector mode as well as in scanning mode.

Increased performances

By using these systems, you will benefit from greater flexibility and from better reliability of performances in microelectronics but also in other processes more traditional, users of optic lithography technologies. Finally, thanks to this, there is no need to use auto-focus systems which are very often the source of problems and the technological limitations rather than being value-adding.

Fields of applications

All our direct laser writing equipment offers a large range of specific write modes ranging from a high aspect ratio microstructuring mode (up to 1X80) to greyscale levels structuration, with unlimited levels of grey, or the writing of micropillars in high density on large surfaces with high rate of writing.

High resolution 3D printer for 3D microfabrication: Dilase 3D

Dilase 3D is a high-resolution stereolithography equipment to produce large volume objects (100X100X50mm3). This high-resolution 3D printer enables you to create micro-structures at micrometric resolution scale. It was designed in partnership with the CNRS laboratory from LAAS in Toulouse for 3D microfluidics, biomedical and 3D biotechnology applications.

Photolithography, because of miniaturization, has become a key technological answer for many scientific and industrial fields

Optical fiber sensors for high resolution temperature measurement

Based on the well-proven technology of fiber Bragg gratings

The temperature sensors developed by KLOE offer not only very high-resolution measurements but also a very high density of measurements points via sensing optical cable (optical fiber).

Optical cables manufactured according to our clients’ specifications

Indeed, the specificities of our technology meet the requirements of applications needing highly sensitive detection (monitoring) and continuous temperature readings along the cable.

To better address the objectives of every project, our optical cables are manufactured according to our clients’ specifications, including the number of sensors to be considered, the positioning along the fiber (regular or irregular) and the selection of a protection tube to meet the specific environmental constraints of the final installation.

Our temperature monitoring systems offer near real-time measurements (few seconds) with no need of post-processing. Measurement resolution is 0.01°C without post-processing and can reach 0.001°C with post-processing.

In addition, depending on your application needs, we can also design the inquiry system in charge of reading the recorded temperatures along the optical cables:

- Its optical source bandwidth is adapted to the number of sensors deployed by measurement cable

- The number of optical cables which can be controlled by a same interrogator is also adjustable

- Its conditioning type can also be designed to meet the requirements related to its specific operating conditions (configurations: mobile / fixed, server cabinet / with or without air conditioning etc.)

The combination of one of our interrogators and our range of measurement cables result in one of the most performing configurations on the market with regard to temperature measurement via fiber optics.