Laser photolithography & UV exposure :

Micromechanics

Micromechanics: laser processing for cutting and drilling

Mechanics, like all other technologies, evolve towards an advanced miniaturization.

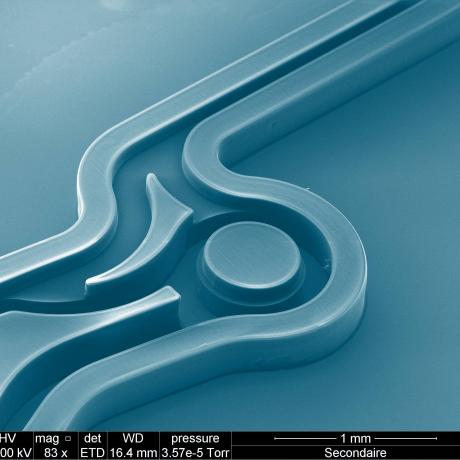

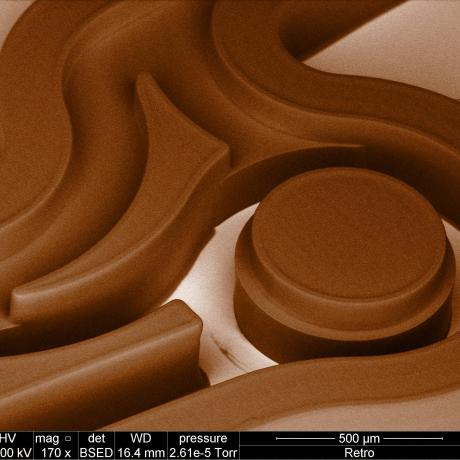

Today, photolithography takes a larger growing part for the setting up of micro-mechanical elements notably in the watch-making industry.

Specific needs of micromechanics

The expected critical dimensions in this sector have progressively changed and called for an enforced adaptation of existing technologies. Thus, the laser processing become more and more used for the cutting and drilling.

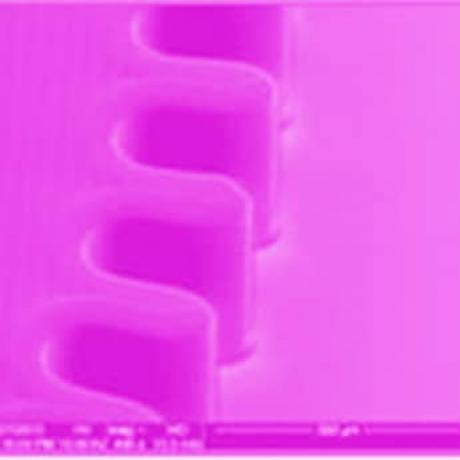

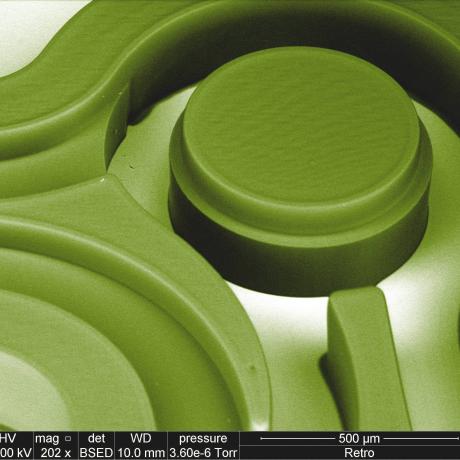

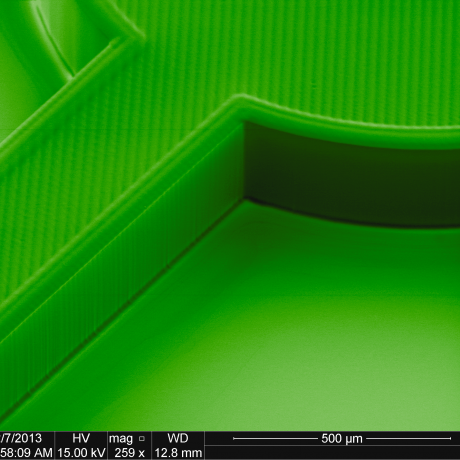

The critical sizes remain at the scale of tens or hundreds of microns in the 3 dimensions, with requested roughness more and more in the range of one micron.

To answer these specific needs, it is necessary that the enforced equipment be able to write in thick layers of several hundred microns with a perfect control of the edge’s verticality while still offering a minimum roughness.

The capacity to write in a dynamically controlled vector write mode and a large depth of focus of the writing beam are the two main properties that are essential to satisfy that sector of activity.

Our direct laser writing technology, the Dilase technology, matches both these essential points.